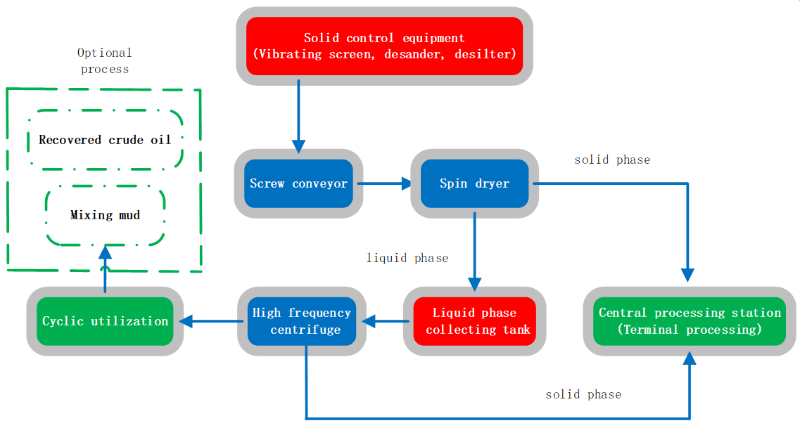

OBM cutting treatment

The solid control equipment of oil-based drilling cuttings produced during drilling is dehydrated by screw conveyor, dryer, high frequency centrifuge and other equipment, and the liquid phase of the overflow is added to the drilling fluid circulation system of the drilling team. It can handle 40 tons of oil-based drilling cuttings per hour without adding any agents, and the oil content of drilling cuttings can be controlled by 3% to 8%. The well site has achieved "no pooling", "reduction", "zero emission" and "zero addition". The purpose of reducing and recovering mud is achieved, and the storage mud pool is eliminated, thus greatly improving the economic and environmental benefits.

Biodegradation process of oil base cutting

The oil-bearing cuttings were mixed with an appropriate amount of biodegradant, and the petroleum hydrocarbons and other organic matter in oil-based cuttings were decomposed by microbial bacteria under suitable temperature, humidity and oxygen conditions, and the soil-cultivable functional restoration and improvement of oil-based cuttings were carried out. Biodegraders contain bacteria and nutrients that are conducive to microbial degradation of oil pollution. It is a kind of environmentally friendly degradation treatment of oil-bearing drilling cuttings with low cost.

Thermal desorption tech

The technology is used under the condition of no oxygen heating to vaporize the liquid phase, and then condense the steam and recover the oil, so as to achieve dehydration and deoiling, and the final solid phase oil content is less than 0.5%, so as to achieve the separation and cleaning of the oily sludge. Thus, the emission of pollutants is reduced and the effective use of resources is realized.