WBM Cutting Without Landing

The waste of different opening times and different mud systems on the site is collected and treated by classification. For the surface layer, the first open water slurry, the rock debris can be treated to make bricks and pave roads; The slurry cuttings of polymer and polysulfonate system are treated and buried safely.

Solids/Water separation & reduction service

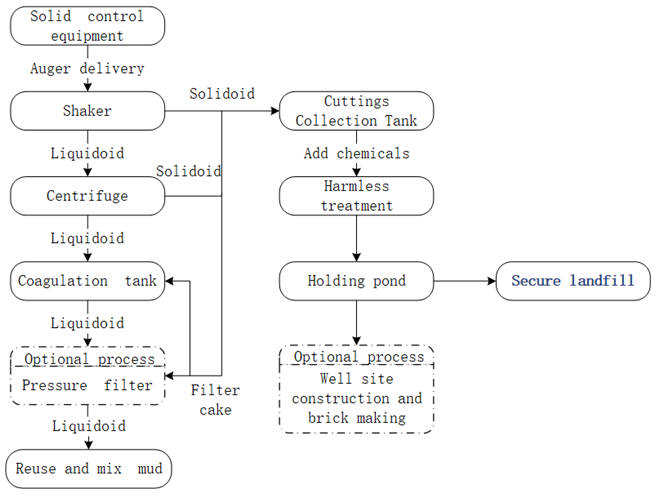

Press filtration and separation reduction services aim to achieve zero discharge of drilling waste by collecting and reducing the waste generated through shale shaker of drilling rigs according to environmental regulations, and further outsourcing for harmless treatment.

Biodegradation

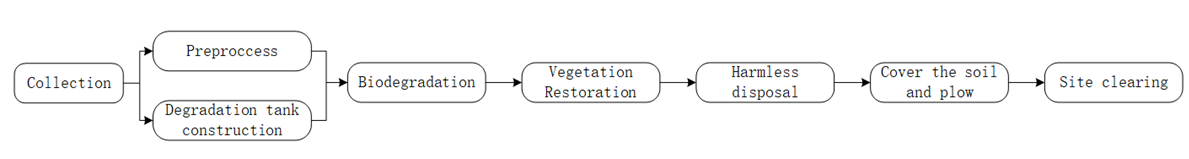

Biological treatment technology has the advantages of saving energy, less investment and low operating costs, and has been widely concerned and valued by domestic and foreign environmental protection industry. Biodegradation is the ideal method to achieve the final treatment of solid waste treatment. The whole process is added with chemical agents, which consumes less energy and is environmentally friendly. After biodegradation, preferred plants can be planted in the soil, and the root microorganisms can further directly or indirectly absorb, volatilize, separate or degrade pollutants, and restore the natural ecological environment and vegetation landscape.

Solidification service while drilling

The waste separated by the shale shaker undergoes secondary drying and screening using equipment such as vertical cuttings dryers and Hi-G dry shaker. Then mixed with solid waste after treated by centrifuge. Subsequently, chemical compounds containing heavy metal chelating agents, stabilizers, and solidifying agents are added to the mixture, thoroughly stirred, and placed. The mixture is transported to a designated solid waste landfill for disposal after 3 days settling and coagulation.