Hardbanding Service

HILONG BoTn Series Hardbanding Material

The BoTn series hardbanding materials are made from Hilong's proprietary - BoTn series patented welding wire, using industry-leading production equipment and welding processes to process on various types of drilling tools. They possess excellent wear resistance and anti-friction properties, significantly improving the service life of drilling tools while effectively protecting casing and reducing drill string rotational resistance. They have been widely used in drilling projects in major oilfields around the world.

BoTn hardbanding provides you with the perfect hardbanding solution, and can meet the higher requirements of harsh wells such as deep wells, ultra-deep wells, extended reach wells and horizontal wells.BoTn series hardbanding products have been evaluated in both international and homegrown third-party authoritative laboratories. Furthermore, BoTn series hardbanding has carried out downhole comparison tests by many oilfield customers such as ENSIGN Canadian drilling in Canada, Tarim Oilfield of PetroChina, Southwest oil and gas Field of Sinopec, etc. These downhole testing results have proven excellent performance, earning recognition from customers and becoming their preferred choice.

The company possesses a professional customer service team and technical experts, providing customers with more timely and professional pre-sales guidance and after-sales service, aiming to enhance brand image and continuously strive to increase customer satisfaction.

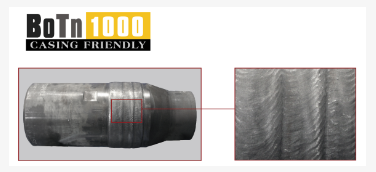

Botn-1000

·Sufficient hardness(HRC58~62)and good anti-wear property which can triple drill pipe tool joint life.

·Excellent friction-reduction property that can reduce the casing wear to the minimum and its wear to casing is only 12% of that of bare tool joint.

· Excellent friction-reduction performance can effectively reduce the torque of the drill string.

·No crack on the surface visible with naked eyes. Good welding properties with less splash and perfect forming.

·BoTn1000 can be applied to surfacing welding for new& used tool joint, heavy weight drill pipe and various downhole instruments surface.

·Compatible with many other kind of hard banding material.

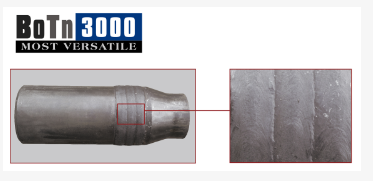

Botn-3000

·Sufficient hardness(HRC58~62)and good anti-wear property which can protect drill pipe to the maximum extent. The wear rate is less than 6% of that of bare tool joint, which can prolong the tool joint service life by three times.

·Perfect friction-reduction property that can reduce the casing wear to the minimum and its wear to casing is only11% of that of tungsten carbide and less than 14% of that of bare tool joint.

·BoTn3000 can be applied to surfacing welding for new &used tool joint, heavy weight drill pipe, drill collar and various downhole instruments surface to withstand the downhole wear and prolong their service life.

·Perfect friction-reduction property that can reduce the torque of the drilling string.

·Good welding property with little splash and good repeat welding performance.

·BoTn3000 is a kind of environment friendly material of chrome-free.

Botn-5000

It provides excellent wear resistance to maximize protection of your drill pipe, even in very demanding drilling environments such as open hole sections in complex formation, extended-reach wells, horizontal wells, deep and ultra-deep wells.

According to the comparative evaluation of 13 kinds of hardbanding wires in the market by the international third-party authoritative institution, BoTn5000 ranks the first in wear resistance. The evaluation result has been published in a prestigious journal.

Therefore, BoTn5000 is the best choice for very harsh abrasive drilling conditions.

The BoTn Special Hardbanding Welding Machine

The BoTn Drill Pipe dedicated hardbanding welding machine is a specialized equipment developed independently by our company with proprietary intellectual property rights for applying abrasion-resistant materials onto drill pipes. This equipment is mainly used for the automatic application of abrasion-resistant materials onto drill pipes, heavy-weight drill pipes, and other downhole tools.

Specialized equipment: To guarantee the application quality, the machine is designed and built specifically for hardbanding welding procedure.

Intelligent machine: Easy and convenient operation is realized by inputting welding parameters into PLC control system.

Automatic unit: The welding process can be completed automatically to reduce the impact of human factors on hardbanding welding quality.

Reliable operation: Designed to adapt to poor service environment (high temperature, extreme cold, dust etc), long working hours and high reliability.